Air Dryers

As the world leader in air drying technology, we can safely boast of an unmatched ability to customize this technology into drying products that match exact and unique applications. Custom applications include size and envelope concerns, withstanding severe shock and vibration along with the ability to survive in dirty, extreme temperature environments. Other challenges include the filtering and drying of severely contaminated hot compressed air, dew point performance tailoring, mounting orientation, and strict AC or DC voltage requirements. The technology leadership of Graham-White is most evident in the heavy rail and rail transit industries worldwide. These markets are where our exceptional track record of fulfilling custom challenges has produced cost effective solutions.

Graham-White is the World's Leading manufacturer of Compressed Air Dryers for use in Heavy Rail, LRV, and Transit applications.

For application assistance, contact Graham-White at sales@grahamwhite.com.

The following parameters should be provided to properly size an air dryer:

- Copies of any pertinent specifications

- Rated output of compressor

- Nominal air flow at the dryer's inlet

- Nominal, min, and max ambient temperatures

- Nominal, min, and max operating pressures

- Nominal and maximum inlet temperatures

- Dryer mounting location

- Required dew-point depression or %RH at outlet with respect to a stated ambient

- Number of locomotives and cars in a typical train

- Whether or not trainline synchronization exists

469-200 Series Air Dryer

The 469-200 Series Transit Spin-on Air Dryer is a state-of-the-art compressed air filtering/drying assembly. This drying system is a combination of some of the most advanced adsorption technology to date. The 469-200 Air Dryer offers spin-on desiccant cartridges for ease of maintenance. Designed by the Graham-White Engineering Team, with input from our customers, this drying system will provide most rail transit industry applications with compressed air that is free of oil, dirt contamination and moisture.

5-in-1 Air System

Product line is discontinued. Service parts are still available. Details are available in the links below. Contact Graham-White for assistance.

975 Series Twin Tower Air Dryer System

The 975 Series Twin Tower Air Dryer System is designed to deliver Dry, Oil Free and Clean air to the entire locomotive and train compressed air system. With almost three decades of service the 975 model has earned its reputation as the most widely used and dependable regenerative pressure swing dryer system in the North American railroad industry.

Information listed below is for the most common product configurations. Contact GW for non-standard product information and/or to confirm part numbers prior to placing orders.

994-100 Series Air Dryer System

The 994-100 Series Air Dryer System is no longer available as a new item. Graham-White continues to offer service parts, R&R service, and Overhaul service for the 100 Series. The 500 Series is now offered in place of the 100 Series when a new assembly is required.

994-500 Series Air Dryer System

The newest version of air dryer to use Graham-White's innovative technology to produce clean, oil-free, dry compressed air for use in locomotives, the 994-500 offers a lower-cost alternative for locomotives operating in the range of 3,000-4,000 hp. The 994-500 is fully interchangeable with the "life cycle cost saving "994-100 series and has half the moving parts of the original 975 Series line, saving the customer both initial and upkeep expense.

994-600 Series AirSmart™ Air Dryer

The newest air dryer in the Wabtec line is the AirSmart™ 994-600 series. The AirSmart™ bring state of the art technology to mobile air drying. Patented architecture and control allow the dryer to purge and switch only based on total demand and inlet conditions. The result is a uniform outlet humidity, drastic reduction in valve cycles and air usage. The data collected is monitored and used for activity based maintenance, fault detection and display and health checks at start-up and on demand. Data can be accessed and downloaded through the programming or real time through the Ethernet connection.

995 Twin Tower Air Dryer System

The custom design features of the 995 Air System make it a perfect match for the rigorous needs of the rail transit industry. Typical rail transit space limitations are of no concern. By design, the 995 Air Dryer System can be mounted inside the present D4 compressor frame. For the ultimate in Dry, Oil free, Clean compressed air and trouble free performance, specify the Graham-White 995 Rail Transit Air Dryer System.

Information listed below is for the most common product configurations. Contact GW for non-standard product information and/or to confirm part numbers prior to placing orders.

997 SeriesTwin Tower Air Dryer System

The 997 is a scaled up version of the 995. The 997 is primarily used by international transit customers where the air flow demand exceeds that of the 995.

QBA15 / QBA60 Air Dryers

The QBA Series Air Dryer truly live up to the Quality Brake Air name. The QBA Air Dryers are equipped to fulfill the critical demands of the stop and go, high air usage, "Severe-Duty" vehicles. Unlike single tower devices, there are no restrictions as to how long a compressor can pump and no minimum compressor unload time is required. The QBA Series Air Dryers combine multiple high efficiency filtration components with twin tower drying technology in one easy-to-install, compact package. When properly applied, installed and with minimal maintenance, the QBA Series will literally transform your operation. Severe-Duty vehicles that have a history of winter brake air line freezing, heavy oil sludge, carbon, water and dirt can now enjoy the trouble free benefits of "Quality Brake Air". Chose from the QBA15 for lower capacity compressor applications or QBA60 for higher capacity compressor applications. Consult Graham White for specific applications.

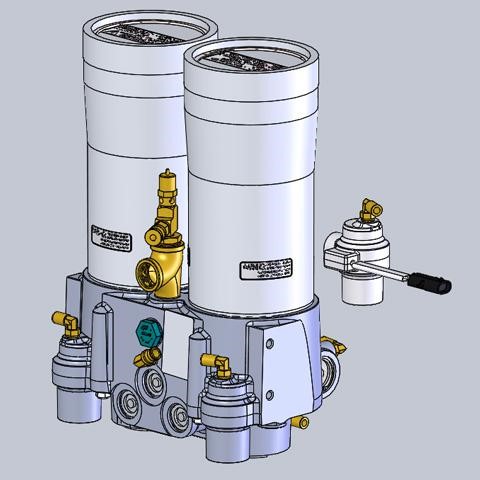

QBA15-CA Air Dryer System

The SludgeBraker QBA15-CA is the rail version of Graham-White's "Sever-Duty" Truck and Bus Air Dryer. Sludgebraker is equipped to fulfill the critical demands of inner city, stop and go, high air usage, “Severe-Duty” vehicles. The QBA15 combines multiple high efficiency filtration components with twin tower drying technology in one easy-to-install, compact package.

The QBA15-CA model is used in the rail market as both a point of use solution on locomotives for protection of RCL valve sets and on MOW equipment applications.

QBA15-CA is designed for flow rates between 10 and 20 scfm at a maximum operating pressure of 150 psi.

QBA15-CA Model does not include the PF15 Prefilter / Scrubber Assembly.